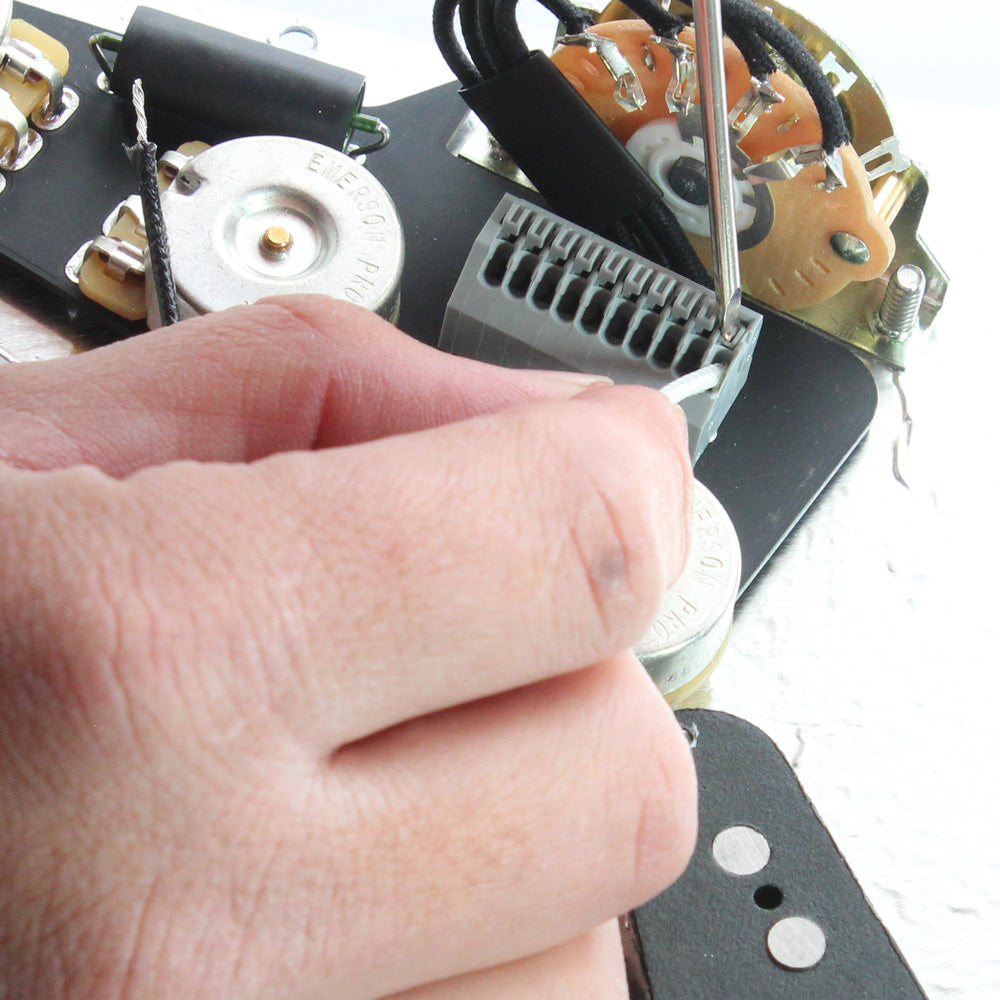

I build various electric guitars and the harness makes it easy foe setting the electronics and pickups.

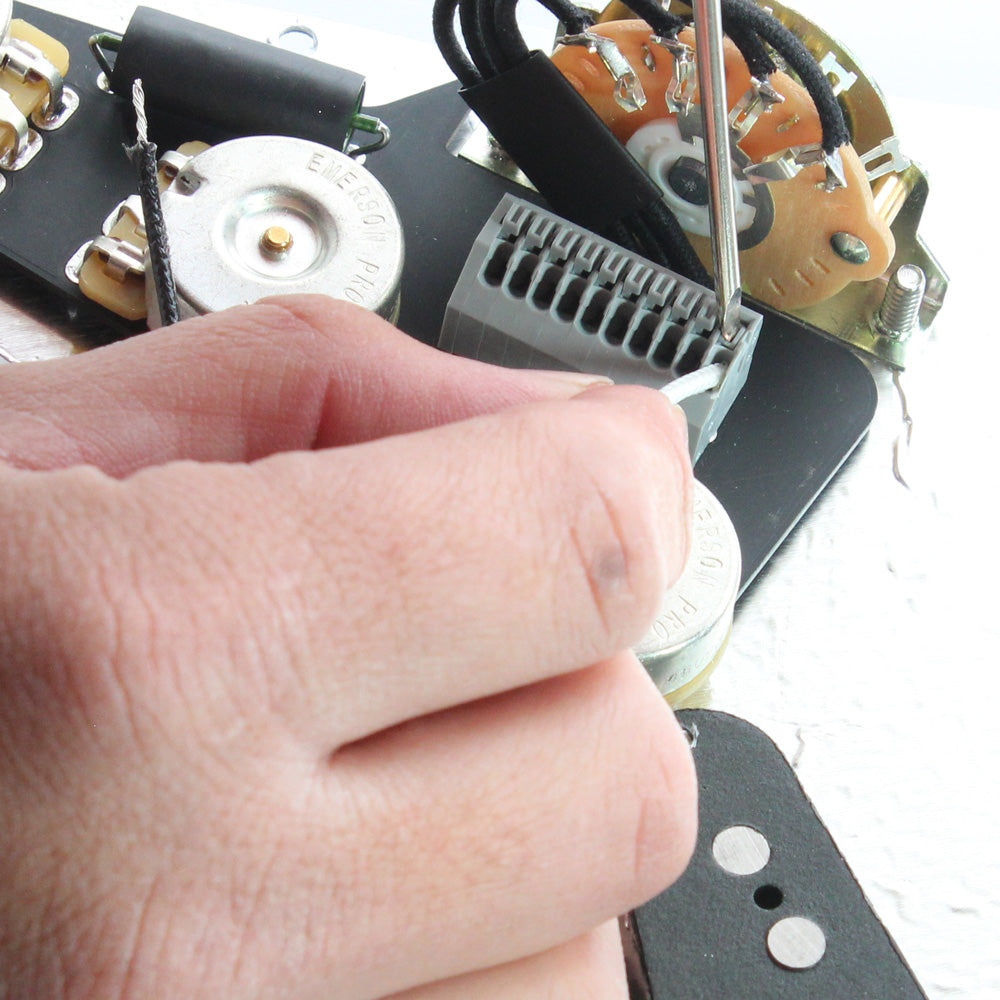

I have used this harness on three Strats, including two recent Classic Vibes. The installation is overall very smooth. With the Squiers you need to manually open up the output jack plate (for me 5 minutes with an awl) and purchase USA spec knobs and switch tip. For that I used the Obsidian package with no issues.

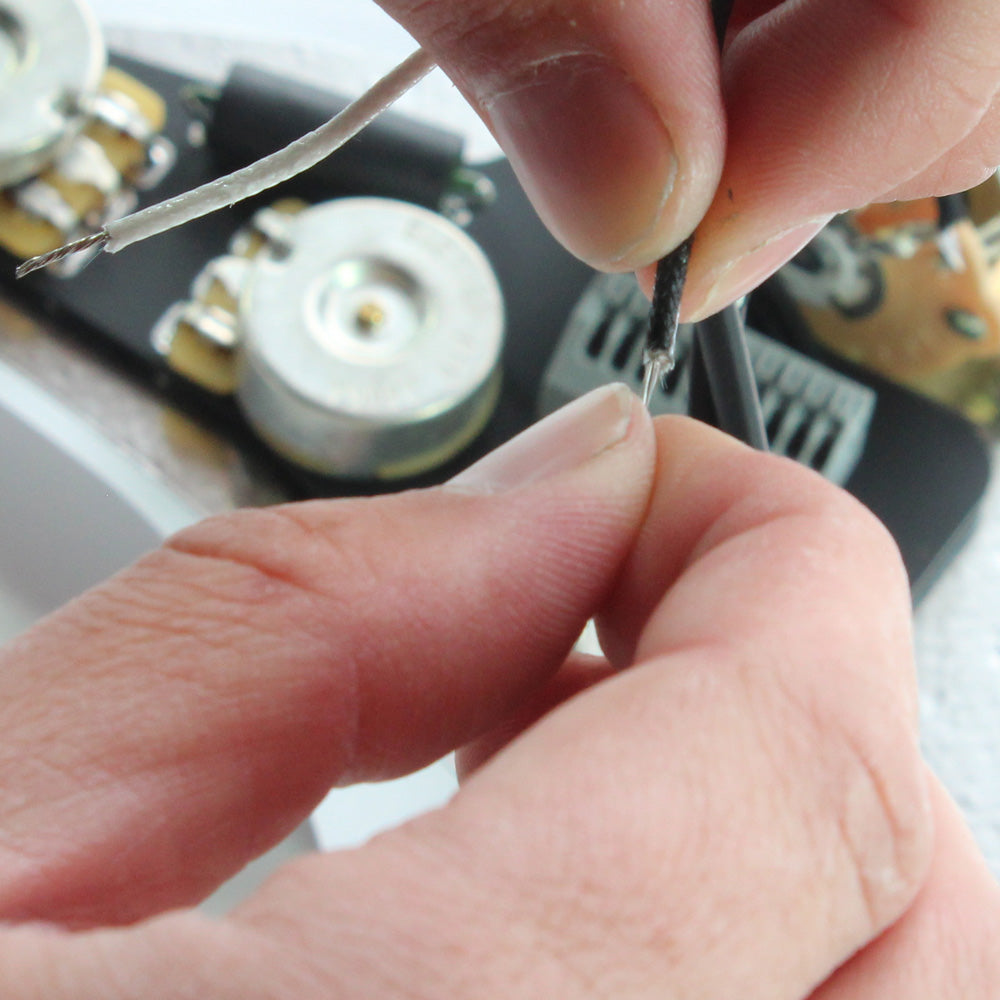

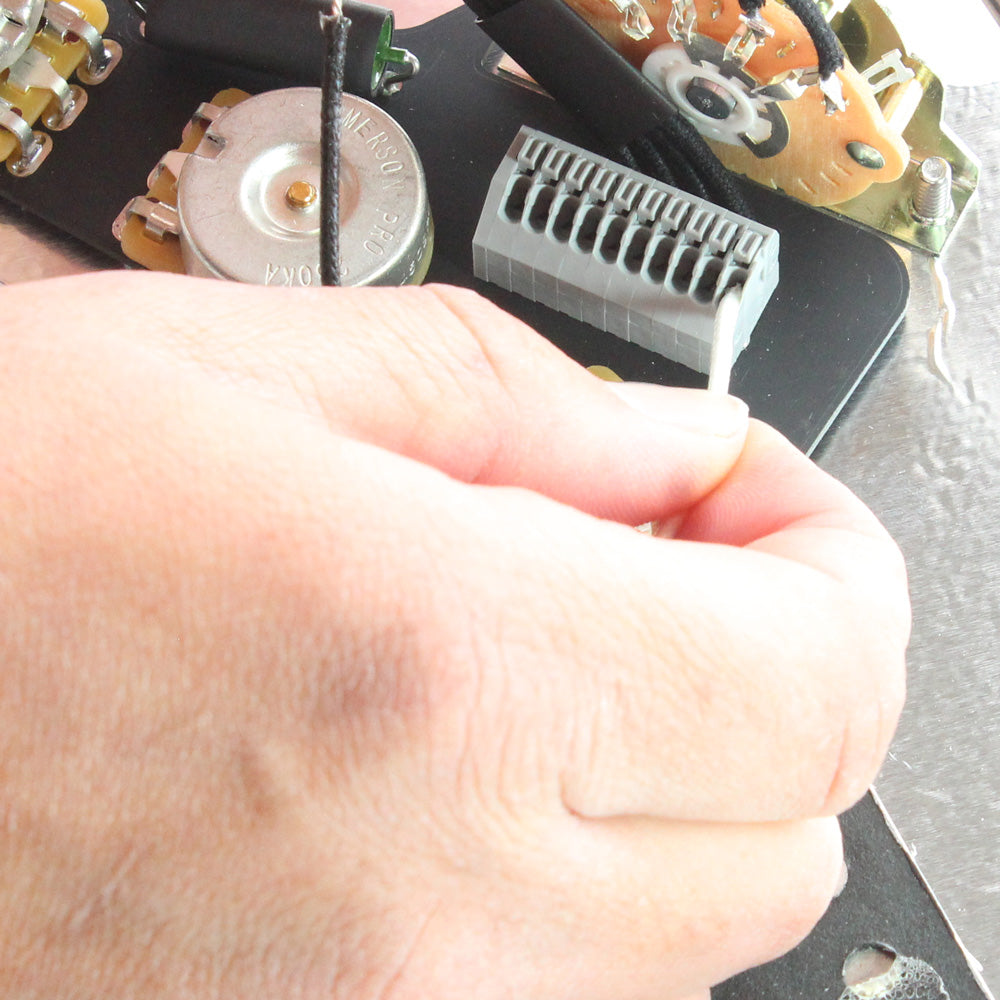

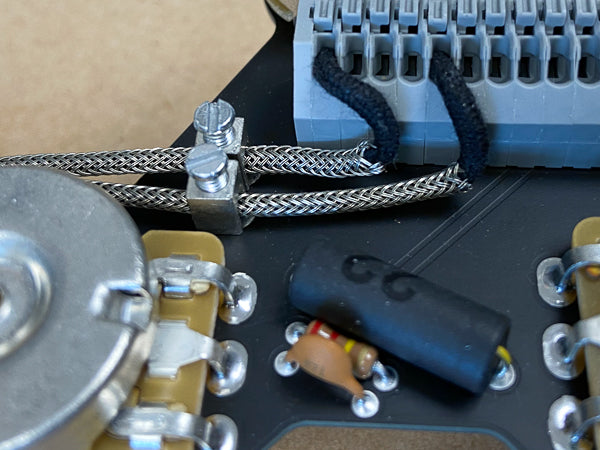

I finally found a Squier CV 60s P Bass worth modding, so this circuit was the starting point. Even with the stock pickup there are definite improvements (particularly with the tone control) so once that Fralin pickup arrives, It'll be all steam ahead. I found fitting the wires into the tiny cavities a little fiddly, but that's probably because of my failing 76 yo eyesight! A very worthwhile investment.

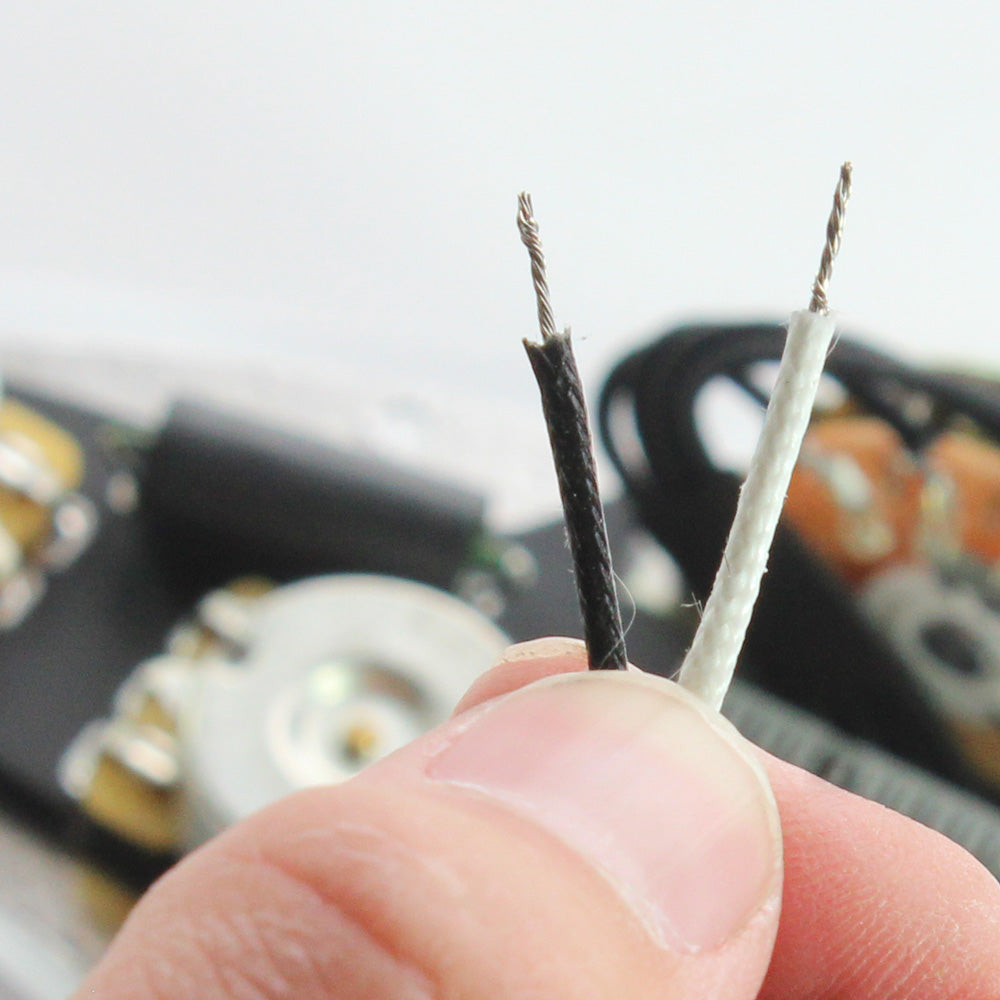

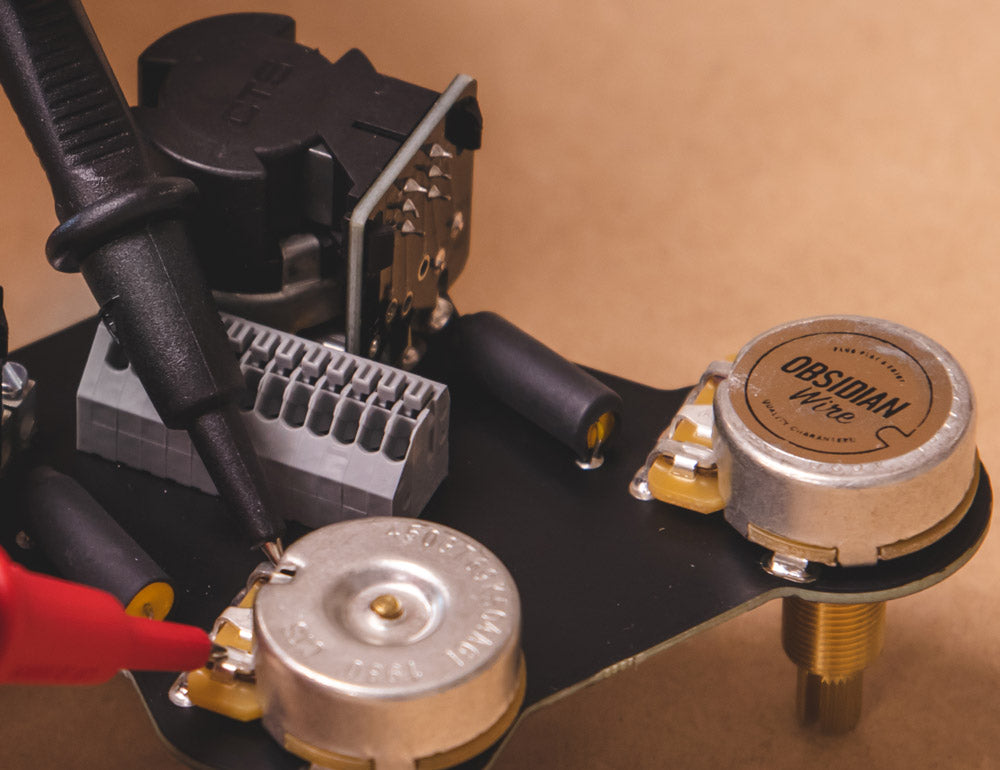

I wanted to upgrade the electronics on a budget entry-level guitar, and this seems to be a great option if you're inexperienced with these kinds of upgrades. I also added a white pickguard that's better than the original one. Installation is easy, and their website has information on potential issues that helped me identify a change in the wire colors on my Toneryder pickups. The 7 ways switch -upgrade option is a significant improvement over the initial. The shipping was fast, with good order tracking, and the packaging was perfect.